Medical Device Software Per IEC 62304

This course is essential for Medical Device companies interested in submitting software enabled medical Devices or Software as a Medical Device to the FDA for 510K approval. One of the biggest risks most company's face when submitting their device for approval is finding out after seven or more months of waiting that the 510K has been denied because the software portion of the submittal is inadequate and not compliant. They also face potential audit risk which might prevent them from selling their approved product if they have been found to not have an IEC62304 Compliant Software Quality System.

This course will ensure that Device companies will know exactly what documentation needs to be prepared. They will also know how to ensure the documentation is prepared correctly so the software portion of the submittal will be in compliance preventing delays of the 510K approval. Companies can also face potential audit risks and serious findings post submittal that can block their ability to ultimately sell their product successfully. This course will ensure that you know what is expected to have in place for compliance for your company during the preparation of a 510K to prevent this risk.

- Why is having an IEC62304 Compliant Software Quality System important to both developing your software for 510K approval and how you can be putting your company at risk post-approval if you do not have a compliant system in place

- What is IEC62304 and how does it differ from other Compliance Standards such as ISO13485

- What are the elements that constitute an IEC62304 Compliant System?

- Benefits of developing to an IEC62304 standard

- What are the components of the Software Lifecycle

- What are the major Software Work Products developed to the standard?

- How it fits in with a Company's Standard Quality Process

- What are the legal consequences for the company with the submittal if the company does not adhere to the Guidance

- One of the most common reasons that a Software Enabled Medical Device is denied a 510K is because the Guidance has not been followed

- What are the potential audit consequences if the Company does not have an IEC62304 Compliance Quality System in place

- Understand the regulatory need for IEC 62304 Guidance as it relates to submitting a 510K for Software Enabled Medical Devices

- What constitutes compliance with the Standard

- What areas does the Guidance Address

- What are the legal consequences for the company with the submittal if the company does not adhere to the Guidance

Developing software for medical devices can be a challenge especially if the device is complicated. You do not know if it is safe enough. You do not know if it tested enough. You do not know if the FDA will consider it for suitability for a 510K. Should your software cause harm to someone you don't know if you are protected from liability should your software fail.

Compliance with IEC62304 is key to ensure your software has been developed to the highest level of safety. Developing software based on the standard shows one way to indicate an intent to ensure the safety of your product. Gives you a framework to ensure you are developing and testing to consistent and stringent standard. Demonstrating compliance with the standard will be apparent in your submission and will be one way to ensure acceptance by the FDA.

Managers, Supervisors, Directors, and Vice-Presidents in the areas of:

- Regulatory

- Quality

- Vice President of Compliance and Regulatory

- Compliance Expert

- Software Engineer

- Software Engineering Manager

- Software Compliance Engineer

- Medical Device Software Engineer

- Quality Assurance

- Design Assurance

- Design Engineers

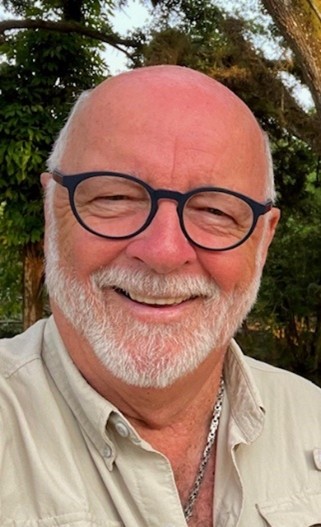

Jose Mora is a Principal Consultant specializing in Manufacturing Engineering and Quality Systems. For over 30 years he has worked in the medical device and life sciences industry specializing in manufacturing, process development, tooling, and quality systems. Prior to working full time as a consulting partner for Atzari Consulting, José served as Director of Manufacturing Engineering at Boston Scientific and as Quality Systems Manager at Stryker Orthopedics, where he introduced process performance, problem solving, and quality system methodologies.

During that time he prepared a white paper on the application of lean manufacturing methods to the creation and management of controlled documents and a template for strategic deployment. Jose led the launch of manufacturing at a start-up urology products company as Director of Manufacturing for UroSurge, Inc. at the University of Iowa's business incubator park in Coralville, IA, creating a world-class medical device manufacturing operation, with JIT, kanban systems, visual workplace and lean manufacturing practices. José worked for 10 years at Cordis Corporation, now a Cardinal Health company, where he led the successful tooling, process development and qualification of Cordis' first PTA (percutaneous transluminal angioplasty) catheter. His medical device experience includes surgical instruments, PTA & PTCA dilatation and guiding catheters, plastic surgery implants and tissue expanders, urology implants and devices for the treatment of incontinence, delivery systems for brachytherapy, orthopaedic implants and instruments, and vascular surgery grafts and textiles.

During his time at Cordis, Jose managed the Maintenance and Facilities Department, taking that operation to a level rated as "tops" by the UK Department of Health and Social Services (DHSS) during one of their intensive audits. Jose managed Manufacturing Engineering as part of the Guiding Catheter Core Team of managers, a team that took the Cordis Guiding Catheter business to lead the market, bringing it up from fourth place. By introducing world-class techniques, the Guiding Catheter design and manufacturing was completely re-engineered for robust design and tooling, under Jose's leadership. He was also instrumental and played a leadership role in the complete re-engineering of the Tooling Control System, including design drafting, the tool shop and technical support. Wherever he has worked, he has a track record of introducing world-class methodologies such as Kepner-Tregoe, Taguchi techniques, Theory of Constraints, Lean Manufacturing, Five S (Visual Workplace), process validation to Global Harmonization Task Force standards, and similar approaches

Upcoming Webinars